Refineries and Processes

-

4 January, 2025

-

10:31 am

-

Petroleum refineries are industrial facilities that process crude oil into more usable products, such as gasoline, diesel fuel, kerosene, and liquefied petroleum gas (LPG)& (LNG). Natural gas refineries process raw natural gas to remove impurities and produce pipeline-quality dry natural gas. Both types of refineries are complex facilities that use a variety of processes to transform raw materials into finished products.

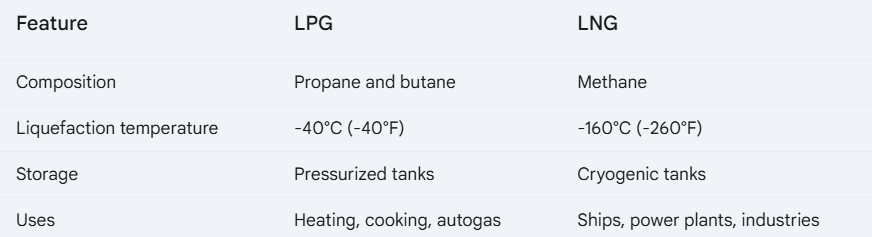

#LPG: is primarily composed of propane and butane. #LNG: is mainly composed of methane.

Petroleum Refining Processes

The refining process for crude oil typically begins with the separation of the crude into different fractions by distillation. This is done by heating the crude oil and collecting the vapors that condense at different temperatures. The lightest fractions, such as gasoline and kerosene, have the lowest boiling points and are collected first. The heavier fractions, such as diesel fuel and lubricating oil, have higher boiling points and are collected later.

After the crude oil has been distilled, the different fractions are further processed to remove impurities and improve their quality. This may involve a variety of processes, such as:

- Cracking: Breaking down large hydrocarbon molecules into smaller ones to increase the yield of gasoline and other light products.

- Alkylation: Combining small hydrocarbon molecules into larger ones to improve the octane rating of gasoline.

- Isomerization: Rearranging the atoms in a hydrocarbon molecule to improve the quality of gasoline and other products.

- Treating: Removing impurities, such as sulfur, nitrogen, and oxygen, from the different fractions.

Natural Gas Refining Processes

Natural gas refining involves removing impurities, such as water, carbon dioxide, and hydrogen sulfide, from raw natural gas. This is typically done through processes such as:

- Absorption: Using a liquid solvent to absorb the impurities.

- Adsorption: Using a solid material to adsorb the impurities.

- Cryogenic separation: Cooling the natural gas to very low temperatures to separate the different components.

API 936

API 936 is a standard developed by the American Petroleum Institute (API) that provides guidelines for the installation quality control of monolithic refractory linings in refineries. Refractory linings are used to protect equipment from high temperatures and corrosive materials. API 936 helps to ensure that refractory linings are installed correctly and will perform as intended.

Environmental Impact

Both petroleum and natural gas refineries can have a significant impact on the environment. They can release air pollutants, such as sulfur dioxide and nitrogen oxides, which can contribute to acid rain and smog. They can also release water pollutants, such as oil and grease, which can contaminate waterways. Refineries can also be a source of noise pollution.

There are a number of ways to reduce the environmental impact of refineries. One way is to use cleaner fuels, such as natural gas. Another way is to use more efficient processes. Refineries can also be designed to minimize their emissions of air and water pollutants.

Refineries play an important role in the global economy. They provide the fuels and other products that we need to power our homes, businesses, and transportation systems. Refineries are also a major source of employment.

| Process Unit | Primary Purpose | Catalyst Used | Typical Operating Temperature (°C) | Typical Operating Pressure (bar) | Main Products | Byproducts/Residue | Refractory Types |

|---|---|---|---|---|---|---|---|

| Crude Distillation Unit (CDU) | Separate crude oil into different fractions based on boiling point | None | 350-400 | 1-2 | Gases, LPG, naphtha, kerosene, diesel, atmospheric residue | Atmospheric residue | Fireclay, insulating castables |

| Vacuum Distillation Unit (VDU) | Further separate atmospheric residue into lighter fractions | None | 400-450 | 0.1-0.5 | Vacuum gas oil, lubricating oil, vacuum residue | Vacuum residue | Fireclay, high-alumina, insulating castables |

| Fluid Catalytic Cracking Unit (FCCU) | Convert heavy fractions into gasoline and diesel | Zeolite | 500-550 | 1-2 | Gasoline, diesel, LPG, olefins | Catalyst coke | High-alumina, silica-alumina, refractory concrete |

| Fluid Coker | Convert heavy fractions into petroleum coke | None | 500-600 | 2-5 | Petroleum coke, gas oil, naphtha | Petroleum coke | High-alumina, fireclay, insulating castables |

| Hydrocracker | Convert heavy fractions into lighter, higher-value products | Noble metal catalyst | 350-450 | 100-200 | Gasoline, diesel, kerosene, LPG | Minimal residue | High-alumina, dense castables |

| Catalytic Reformer | Increase the octane number of naphtha | Platinum or rhenium on alumina | 450-550 | 10-35 | High-octane gasoline, hydrogen | Minimal residue | High-alumina, dense castables with low iron content |

| Hydrotreating Unit | Remove sulfur and other contaminants from petroleum fractions | Cobalt-molybdenum or nickel-molybdenum catalyst | 300-400 | 20-70 | Desulfurized products | Minimal residue | Fireclay, high-alumina, chrome-based refractories (for high-temperature applications) |

| Alkylation Unit | Combine isobutane and light olefins to produce high-octane gasoline | Sulfuric acid or hydrofluoric acid | 10-20 | 7-14 | Alkylate (high-octane gasoline) | Minimal residue | Acid-resistant bricks, carbon bricks, fluorocarbon linings (for HF) |

| Isomerization Unit | Convert straight-chain paraffins to branched-chain isomers to increase octane number | Platinum on chlorinated alumina | 120-180 | 20-30 | Isomerate (high-octane gasoline) | Minimal residue | Low-cement castables, high-alumina |

| Visbreaking Unit /Thermal Cracking | Reduce the viscosity of heavy residues | None | 450-500 | 5-10 | Lighter fuel oil, gas oil | Minimal residue | Fireclay, high-alumina |

| Delayed Coking Unit | Produce petroleum coke from heavy residues | None | 450-500 | 2-7 | Petroleum coke, gas oil, naphtha | Petroleum coke | High-alumina, fireclay, insulating castables |

| Solvent Deasphalting Unit | Remove asphaltenes from heavy residues | Propane or butane | 50-80 | 30-50 | Deasphalted oil (DAO) | Asphaltenes | Stainless steel, low-temperature castables |

| Lube Oil Processing Units | Produce lubricating oils from vacuum gas oil | Various catalysts and processes | Varies | Varies | Lubricating oils, waxes | - | Fireclay, high-alumina, insulating castables |

| Amine Treating Unit / Sulfur Recovery Unit | Remove hydrogen sulfide (H2S) from gas streams and convert it to elemental sulfur | Amine solution / Claus process catalyst | Varies | Varies | Clean gas streams / Elemental sulfur | Minimal residue | Acid-resistant bricks and linings, specialized refractories for sulfur recovery |

| Sour Water Stripper | Remove H2S and ammonia from wastewater | Steam stripping | 100-120 | 1-2 | Clean water | Minimal residue | Corrosion-resistant materials, often with specialized coatings |

| Gasification Unit | Convert hydrocarbons into synthesis gas (carbon monoxide and hydrogen) | Nickel or other metal catalysts | 900-1500 | 20-70 | Synthesis gas | Ash | High-alumina, chrome-magnesite, silicon carbide |